Total Milling

Total milling services encompass a wide range of machining operations and applications designed to shape, cut, and create intricate components from various materials. At DK General Metal Work, total milling includes the following specialized services:

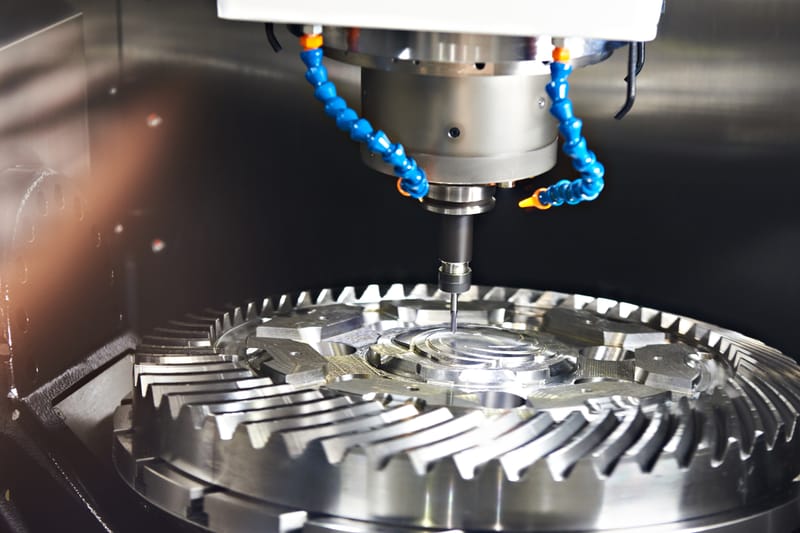

1. Gear Cutting and Shaping

- Manufacturing precise gears for various machinery applications, including spur, helical, bevel, and worm gears.

- Ensuring accurate tooth profiles for optimal engagement and performance.

2. Spline and Keyway Milling

- Machining splines and keyways for shafts, ensuring proper transmission of torque.

- Custom designs for specific mechanical requirements.

3. Surface Milling

- Flattening, smoothing, or creating specific patterns on metal surfaces for functional and aesthetic purposes.

- Providing the perfect finish for parts used in construction, manufacturing, or engineering projects.

4. Slotting and Grooving

- Creating precise slots and grooves in components for interlocking or assembly.

- Used for fasteners, brackets, and custom metal applications.

5. Thread Milling

- Cutting internal or external threads into cylindrical parts with exceptional precision.

- Ideal for producing components such as threaded pipes and bolts.

6. Profile Milling

- Shaping intricate profiles and contours for custom-designed components.

- Includes 3D surface machining for mold and die making.

7. Face Milling

- Milling wide, flat surfaces to achieve a smooth or specific texture.

- Commonly applied in preparing metal blanks for further processing.

8. Pocket Milling

- Creating recesses or pockets within a material for applications like housings, enclosures, or cavities in mechanical parts.

9. Milling of Machine Parts

- Custom fabrication and fine-tuning of various machine parts used in industries like construction, agriculture, and manufacturing.

10. Reverse Engineering for Worn Parts

- Recreating or repairing damaged components by milling replacement parts tailored to original specifications.