What Is Metal Machining?

Metal machining is a precision manufacturing process that involves the removal of unwanted material from a workpiece using various cutting tools and techniques. At DK General Metal Work, we specialize in advanced metal machining processes that transform raw metal into high-quality, precision components tailored to meet specific industrial and commercial needs.

The Basics of Metal Machining

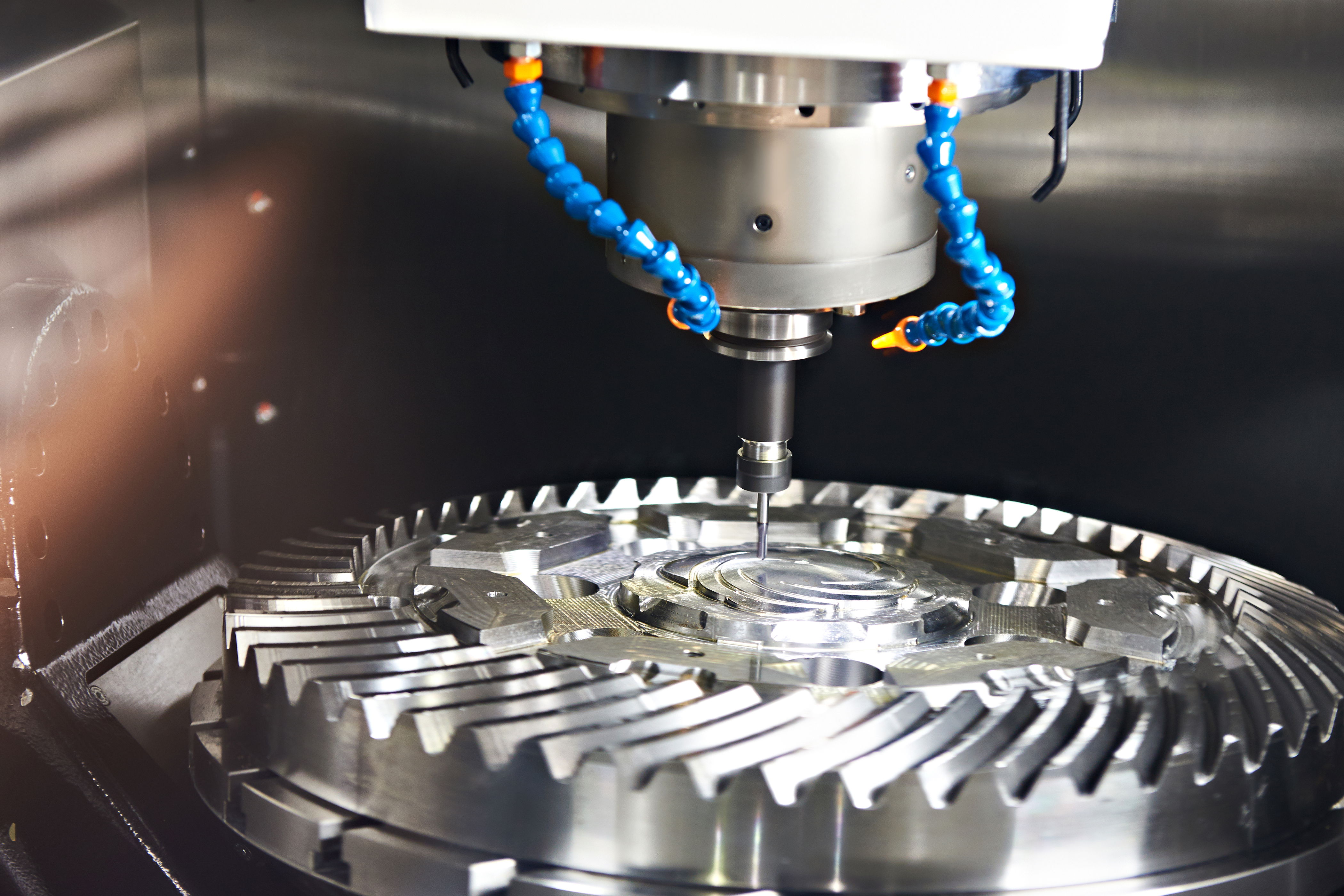

At its core, metal machining is a subtractive process. This means that material is systematically removed from a larger block of metal—often using computer numerical control (CNC) machines—to achieve the desired shape, size, and surface finish. Unlike additive processes such as welding or 3D printing, metal machining focuses on carving out a final product by cutting away excess material.

Key Processes in Metal Machining:

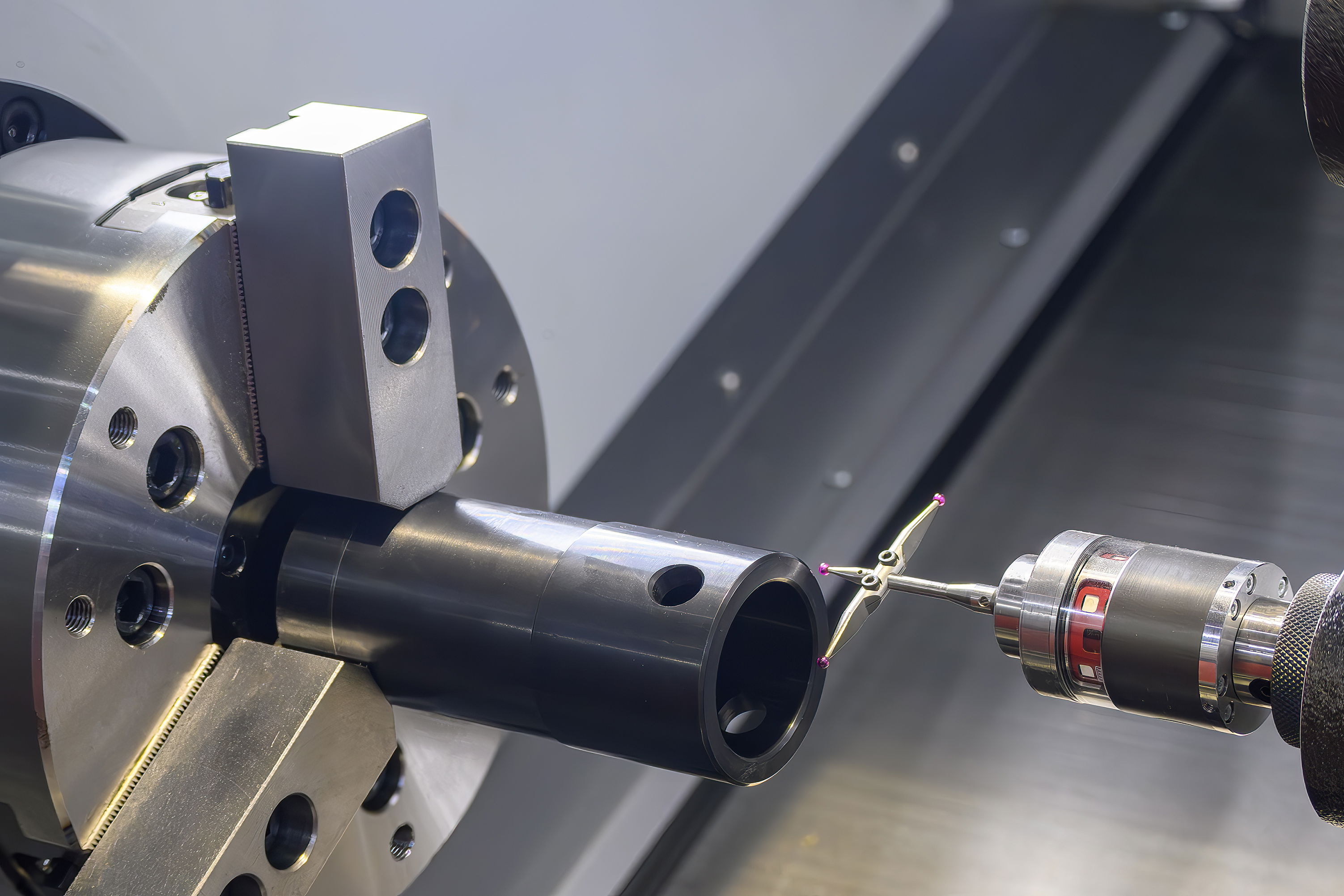

- Turning: Involves rotating the workpiece while a cutting tool removes material to create cylindrical shapes. This process is often performed on a lathe.

- Milling: Uses rotating cutting tools to remove material from a stationary workpiece, enabling the creation of complex shapes, gears, and teeth.

- Drilling: The process of creating holes in the workpiece with a drill bit.

- Grinding: A finishing process that uses an abrasive wheel to provide high precision and a smooth surface finish.

Techniques and Technologies

Modern metal machining heavily relies on computer numerical control (CNC) technology. CNC machining offers several benefits:

- Precision: Automated control systems ensure that cuts are made accurately according to design specifications.

- Repeatability: Once a program is set up, the machine can produce identical parts over and over.

- Efficiency: CNC machines can operate continuously, reducing production times and minimizing errors.

In addition to CNC, traditional manual machining techniques still hold value for bespoke or low-volume projects. At DK General Metal Work, our blend of cutting-edge technology and experienced machinists ensures that we can handle projects ranging from simple parts to complex assemblies.

Why Metal Machining Is Essential

Metal machining is critical in various industries due to its ability to produce components with tight tolerances and high-quality finishes. Whether it’s for automotive, aerospace, construction, or industrial equipment, precision-machined parts play an essential role in ensuring the reliability and safety of end products.

Benefits of Metal Machining:

- Customization: Tailor-made components can be designed and manufactured to meet unique specifications.

- Durability: Precisely machined parts are robust and can withstand demanding operational environments.

- Cost-Effectiveness: Especially in large-scale production, machining can be more economical compared to alternative methods, thanks to its high repeatability and efficiency.

Applications of Metal Machining at DK General Metal Work

At DK General Metal Work, metal machining is at the heart of our operations. We use advanced turning, milling, and grinding techniques to produce a wide range of products:

- Custom Machine Components: From gears to shafts, our machining processes ensure that every part meets stringent quality standards.

- Repair and Maintenance Parts: We produce precision replacement components that restore the functionality of existing machinery.

- Innovative Designs: Our state-of-the-art machinery allows us to execute complex designs that push the boundaries of traditional manufacturing.

By leveraging a mix of modern technology and skilled craftsmanship, DK General Metal Work has built a reputation for delivering durable and reliable metal parts that drive the success of various industries.

Conclusion

Metal machining is more than just a manufacturing process—it is a blend of art and science. Through precise material removal and state-of-the-art CNC technology, it creates components that are critical to modern industry. At DK General Metal Work, our commitment to excellence in metal machining ensures that every piece we produce meets the highest standards of quality, precision, and performance. Feel free to contact us if you have any questions about our metal machining services or need a custom solution for your next project.